|

|

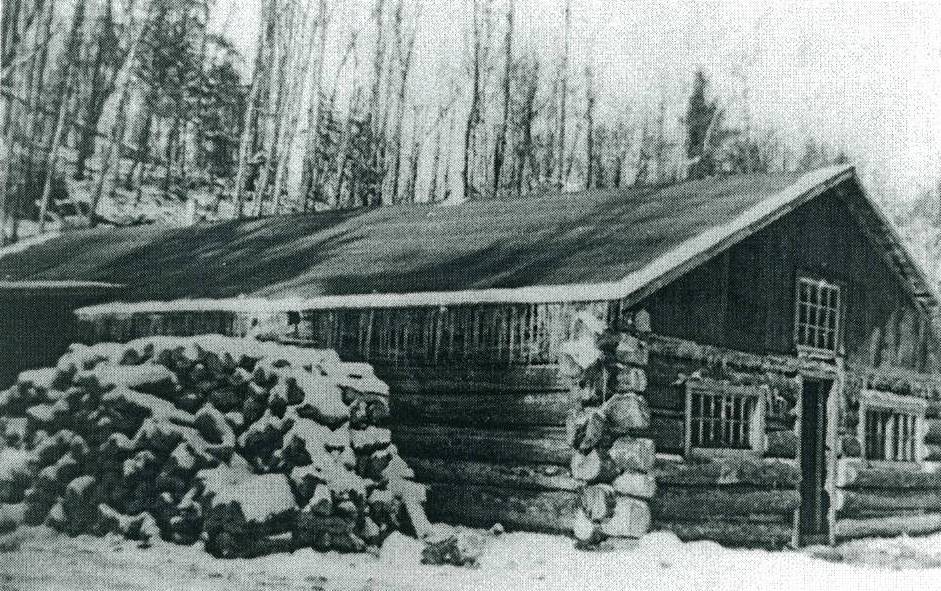

The Muskoka Wood Manufacturing Company sawmill and hardwood flooring plant on Hunter’s Bay, Huntsville (Bob Hutcheson) |

The Muskoka Wood Manufacturing Company was started in 1901 by the Hutcheson family, including R. J. Hutcheson and W. E. Hutcheson. There were other shareholders: Dr. Hart of Huntsville Hart House, Dr. Hilliard, whose family came from Ireland with the Hutchesons, and the Argles sisters from New York, who were related to the Hungerfords from Lumina Resort. C. S. Parkinson was our accountant in 1906, and Walter Hanes and George Bushfield were foremen. Eventually the company became owned by R. J. Hutcheson, Frank W. Hutcheson, Harry M. Hutcheson, and R. Arthur Hutcheson.

Harvesting Hardwood

The company acquired the sawmill from the Whaley Lumber Company on Hunter’s Bay in Huntsville. They immediately built a hardwood flooring plant to use the lumber that had knots in it. All of the large clear (free of knots) hardwood was easy to market because it was used for furniture and in many industries, including car frames and bodies for station wagons and trucks. Hardwood flooring was made using the sound, clear wood between the knots of the more knotty boards. This plant made the potential for hardwood harvesting much greater than it had been, and also helped other sawmill operators to get rid of the boards with knots in them at a profit. The timing was good, as much of the hardwood in southern Ontario had been harvested or burned to make room for farms.

Land from Settlers

Under the free grant act of 1868, settlers over the age of 18 could acquire up to 200 acres. They were allowed to locate on the land, but there was no patent or deed until after five years of location. Settlers were required to have 15 acres under cultivation, have built a house suitable for habitation at least 16 feet by 20 feet, and have actually continuously resided upon and cultivated the said land for a term of five years.

Many people had great trouble clearing the 15 acres and asked for help from the lumber companies. The lumber companies did help. Settlers could buy additional acreage for 50 cents an acre. The lumber companies also made offers to the settlers: if they wanted to vacate at any time after the land was acquired, the companies would offer them a dollar an acre for their land. Since many could not make a living even though they were hard workers and intelligent people, they were forced to vacate and came to the lumber companies to pay them something for their previous hard work and the land.

Therefore over the years a lot of land was sold to the lumber companies, because it was not useful for anything else at the time, without a major struggle for the settlers. Often this land was on the rivers and lakes as the method of transporting logs to the sawmill, where they would be cut into lumber, was via the waterways. Much of the land that the Hutchesons acquired in the early 1900s before 1920 cost a dollar an acre, and by 1955 there was still a lot of land available for that price. It took a long time for this land to be valuable.

An interesting side note is that, when Champlain passed north of Algonquin Park in the early 1600s, he called the country the “Grand Brûlé” (big burn). The trees that grew matured at about the same time as the settlers arrived from Europe.Company Operations

The Muskoka Wood Manufacturing Company accumulated a tremendous amount of land, approximately 100,000 acres, including a number of lots around Bella and Rebecca Lakes. The company had considerable property in Sinclair and Finlayson, plus six more townships and Crown timber limits in Sinclair, Bethune, Finlayson, McCraney, Proudfoot, Hunter, Peck, and Butt Townships. Most of the timber was floated on waterways until 1935.

The Hutcheson family had rules that when timber was cut beside lakes that the skyline view was not to be disturbed so timber was not cut close to the lakes. Many companies cut right down to the lakes and even cut timber off the islands. Hutcheson family policy was to try to make the land look as undisturbed as possible so that people could enjoy nature as it was when settlers first came to the country.

The allocation of who could have a licence to operate on Crown lands was administered by the Ontario Department of Lands and Forests. At one time the contact was the Superintendent of Algonquin Park, Mr. Frank McDougall, for whom the road through Algonquin Park is named. Of interest is that he was both an administrator and a pilot; he lived in a log cabin on Smoke Lake in Algonquin Park and played a Stradivarius violin!

Before 1935 nearly all of the accessible timber was sent down the Big East River through the dams owned by the Big East River Improvement Company, which were used to manage the water levels. This company was privately controlled rather than government controlled as it is today. The rest of the Company’s timber was either sawn at a sawmill on Brule Lake or shipped by rail on the railroad in Algonquin Park to Huntsville. Rivers and railroads were the main form of transporting nearly everything as roads were primitive, and vehicles were not built heavily enough to carry big loads.When the logs arrived at the mouth of the Big East River, the hardwood logs were put into cribs made of white pine or spruce logs with chains hanging between the two outside logs. The chains would support the hardwood logs and stop them from sinking. The softwood would float in a large circle of boom logs. Both the cribs and the booms of logs had to be towed about two miles to the sawmill on Hunter’s Bay in Huntsville. This was done with a boat called a pointer or a steam boat powered by a wood burning boiler.

From Sinclair to the World

During World War II, an airplane called a Mosquito was made almost entirely of yellow birch veneer, and some of the logs that provided it grew within sight of Bella and Rebecca Lakes.

In the days of Muskoka Wood Manufacturing, the plant was run by a variety of steam engines and electric motors, the steam being generated from sawdust and trimmings from the process of the hardwood plant and the sawmill. The sale of the rest of the wood trimmings to home owners to heat their houses paid for the company’s milling operations.

Annually this company handled several million feet of wood and employed about 350 people.

Birch and maple hardwood flooring made from trees harvested around Bella and Rebecca Lakes was shipped all over North America to Europe, United Arab Emirates, Hong Kong, and other places all over the world.

From 1901, for 100 years, hardwood flooring made in Huntsville was shipped successfully with some of the logs coming from Sinclair Township. By early 2000, hardwood flooring could be made in China and shipped to Toronto more cheaply than cutting the trees in Sinclair Township, manufacturing in a paid-for plant in Huntsville only 25 miles away, and shipping the flooring to Toronto.

William Robert (Bob) Hutcheson is a grandson of R. J. Hutcheson, one of the founders of the Muskoka Wood Manufacturing Company.